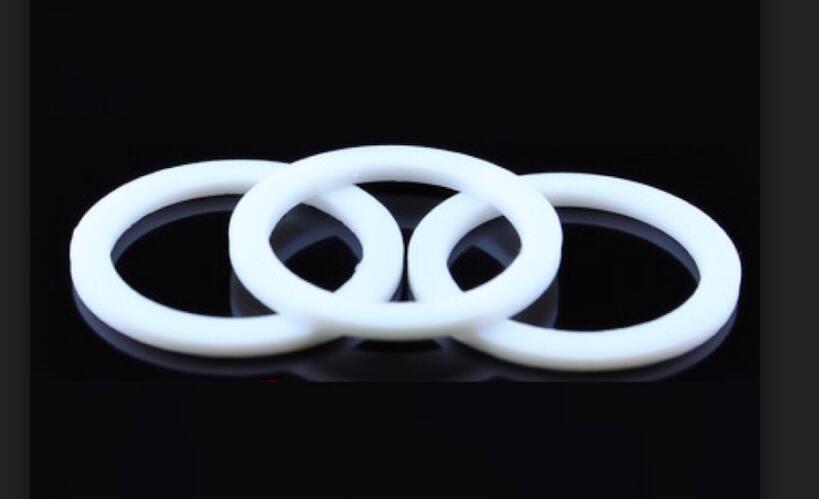

Spiral shaft seals with one or more PTFE Ring are intended to withstand dynamic situations, high temperatures, high weights and dry running that conventional outspread shaft seals made of elastomeric fixing lip materials cannot withstand. A large portion of the PTFE mixes is FDA endorsed.

Fundamental points of interest of PTFE seals include:

- High concoction resistance

- Withstand speeds up to 30 m/s (5 900 ft/min)

- Wide working temperature range, –70 to +250 °C (–95 to +480 °F)

- Withstand weights up to 3,5 Mpa (500 psi)

- Withstand dry running

Establishment Tips for PTFE Ring

Shielding the PTFE O-Rings from getting scratched or gouged amid establishment is vital. Gouging can happen while extending the O-Rings over sharp shoulders or strings. It can be evaded by using so as to stack rings over sharp zones apparatuses or giving corner breaks or radii. Moderate extending, if conceivable underneath 10%, is suggested amid the O-Ring establishment. The utilization of a hot oil or water shower encourages more prominent stretch as required. Outline changes or extraordinary systems might be required for stretch circumstances more than 20%.

PTFE O-Rings can be manufactured from an assortment of mixes, for example, graphite-filled PTFE, bronze and glass. Much of the time, the prerequisites can be met with unfilled PTFE.

Few Applications of PTFE Ring

Ultra-sturdy PTFE Ring is appropriate for static, low weight applications. They show the most flexible concoction similarity since they are manufactured with dormant materials. Resilience’s on the mating equipment parts ought not to permit a major crevice while using O-Rings for seals. Unfilled PTFE materials are helpless against chilly stream, bringing about their expulsion into gathering holes when introduced without go down rings. All O-Rings are perfect with its Back-up rings to give successful static fixing to high-weight applications. The administration life of the O-Rings is definitely enhanced on the grounds that Back-up rings’ capacity is in the region of the expulsion crevice.

Advantages of using PTFE Ring

The accompanying are the upsides of PTFE Ring:

- O-Rings are one of the perfect answers for low-weight frameworks

- Widespread compound similarity of PTFE

- Expansive temperature scope of between — 320 °F and +500 °F

- Quick evaluating and incite pivot

- Wide size determination of O-Rings somewhere around 0.110″ and ~40″; extraordinary estimating is accessible upon solicitation

- Vacuum to high-weight, when utilized as a part of conjunction with suitable move down ring

These sorts of PTFE ring highlight a side furrow to encourage the liquid to drive them against the mating equipment segments for static and a couple of element conditions.

Post time: Mar-09-2016